How the system will does the job:

The system carries out this function automatically, each time a JIT call is received. In this way it assigns each call component transmitted to a components group type. The components group type then takes on the internal control of the call components.

With sequenced JIT calls for assemblies, the system assigns several call components to the same components group type. With the other call types the call components and the components group type form a logical unit and the system therefore assigns a different components group type to each call component.

In the components group determination the system compares whether the characteristics of the call components match a components group type. As soon as it can assign a call component, it continues with the next one. In the profile for the components group determination you can define with which priority the system should consider the various characteristics. The system determines the relevant characteristics of the call components as follows:

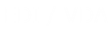

JIT customer

The JIT customer is made up of the sold-to party and the partner description and can therefore be taken from the IDoc.

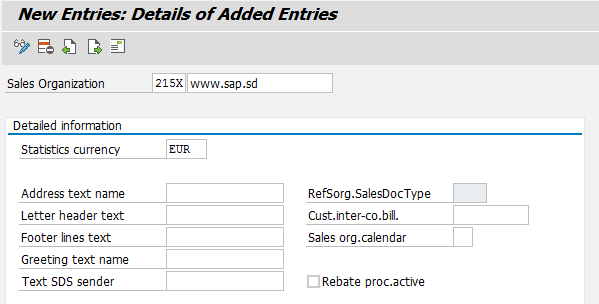

Unloading point and assembly location

The unloading point and, if necessary the assembly location, are also transmitted with the JIT call. The system can also take these characteristics of the call components from the IDoc.

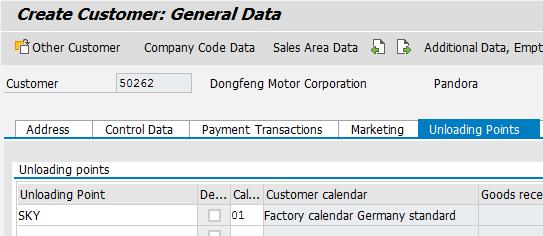

Components group material

The JIT customer generally transmits the components group material with a call. You have several options for defining the components group material of the call component before the components group determination.

You can realize an individual components group material determination using a customer exit. This is particularly recommended for sequenced JIT calls for assemblies, due to the large number of variants.

If you use the process for discrete materials, you can transfer the material of the call components as a components group material.

If you use the process for discrete materials and exactly one components group material can be assigned to a call component, you can transfer the configurable material of the call component as a components group material. To do this you must have entered the configurable material in the material master of the call component in the tab page Basic data 2 in the field Cross plant conf.mat.

Production version

You can also assign the production version using a customer exit. The production version allows you to assign two otherwise equal call components to different components group types, to produce them on different production lines, for example.

There are also call types – please follow the below link:

Call Structure and Call Types